FuseBone

Customised bioactive ceramic implants

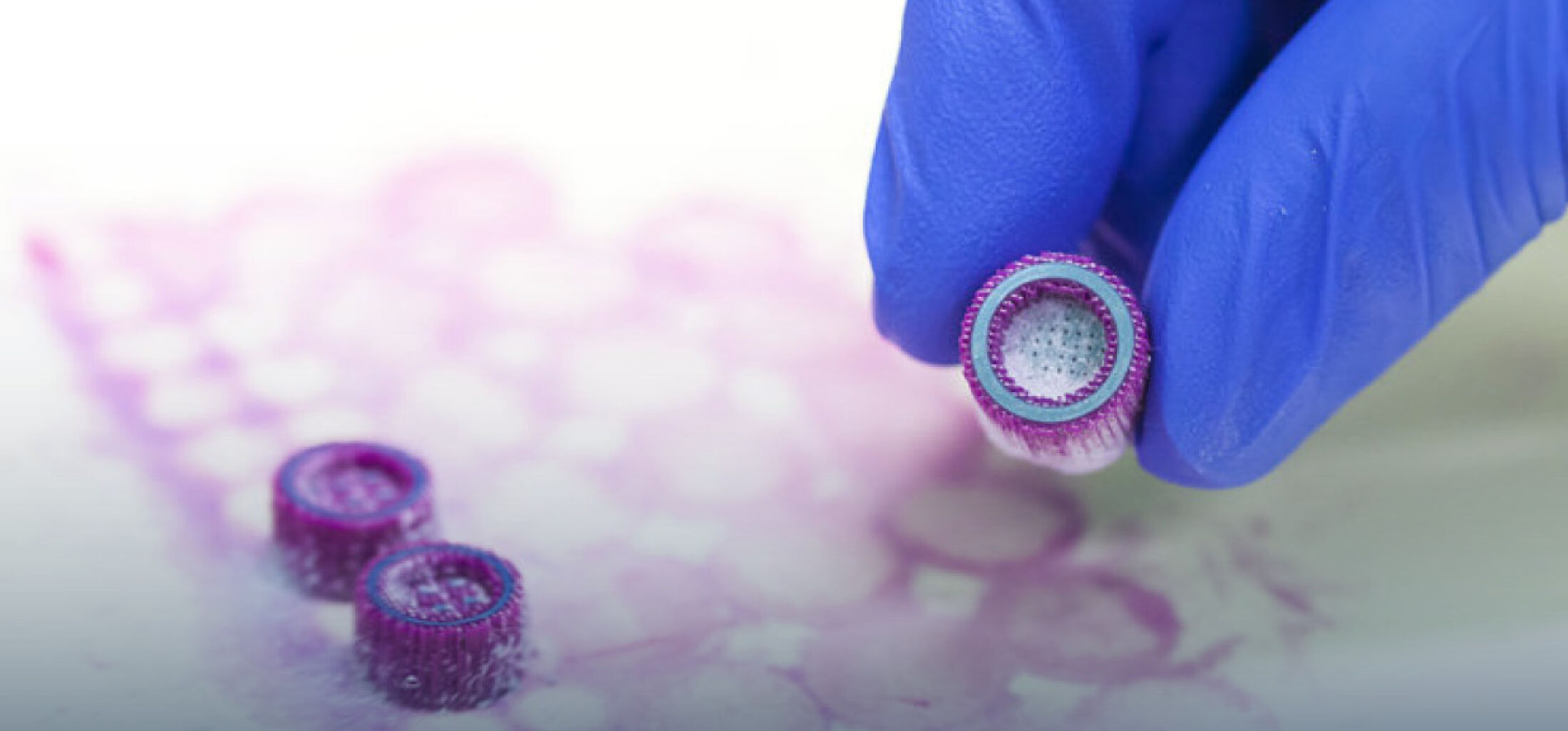

In the joint research project implants for bone replacement on basis of calcium phosphate cement are developed in cooperation with the University Hospital in Maastricht (azM) and TNO Eindhoven. The implants are generated using generative manufacturing without any thermal post treatment.

The generative manufacturing method used in the project is “Fused Deposition Modelling” (FDM). It allows the construction of scaffolds by assembling thin material threads in layers. The model of the scaffold is generated first as dataset from a computer tomography of the bone defect. After the conversion of the CT data into the virtual model the scaffold is generated with the FDM method. The macro porosity of the scaffold can be adjusted by varying the alignment and the distances of the threads. Thereby an ideal structure for vascularisation of the scaffold can be prepared. The material is a customized, paste-like composition based on calcium phosphate and organic additives. The advantage of this material is the “cold” processability, which allows the incorporation of drugs or bone growth factors during the generative manufacturing. These medical additives can be released during the whole biodegradation time and take their effects directly in the area of the bone defect.

The project is funded within the program “Pieken in de Delta” by the Dutch Ministry of Economical Affairs together with the provinces of Noord Brabant and Limburg.